Electron-beam Lithography is the process in which the focused beam of electrons is scanned in order to display the customary shapes to a surface that is having a covering of an electron-sensitive film known as a resist.

EBL is famous for a very unique technique of creating extremely small fine patterns which are then used in the production of integrated circuits. The Electron Beam Lithography system follows the principle which is related to photolithography. As the scanned beam of electrons focuses on the resistor, it tends to change the solubility properties with respect to the energy which gets deposited with the electron beam.

However, the electron beam lithography is more durable in creating high -resolute patterns, and some extraordinary patterns for whose production other processes such as the production of photomask take huge amounts of time.

As electrons are made use for the formation of patterns used for the lithography i.e., the patterns on the semiconductor would allow the electrical properties and other constituents that are required for the formation of a complete circuit. Since this whole system is based on electrons and that is the reason it is known as electron lithography.

First electron beam lithography, machines that were based on scanning of electrons on a surface, was produced during the 1960s.

Many of the research institutes and physical laboratories that indulge in the study of circuit systems or doing research for the fabrication of patterns on the semiconductor are in need of the instalment or management of the Electron Beam Lithography System.

There are many Electron Lithographic companies that indulge in selling lots of electron beam appliances to various places such as research centres, laboratories, National laboratories, Research Universities and many related industries in this field.

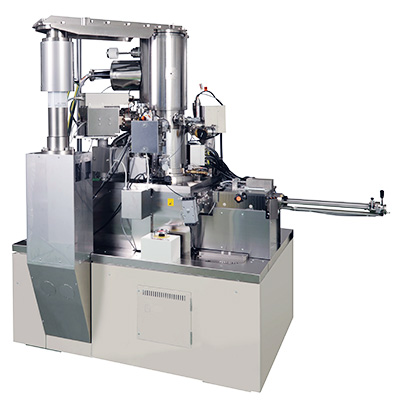

Elionix Beam Lithography Company is one of the renowned company that got established in 1975. From then it has been in the production, instalment and management of the services related to the Electron Beam Lithography systems. This company has sold more than 400 Electronic Beam Lithographic systems to many of the research and industrial institutes. The tools which are majorly used by Elionix are majorly used to have ultra-high-precision for the fabrication of tiny Nanostructures.

The systems installed by Elionix company are capable of producing high-speed production lines with excellent reliability and with affordable cost of ownership.

ESSENTIAL FEATURES OF ELECTRON BEAM LITHOGRAPHY SYSTEM

- Known for providing the highly resolute customary patterns that to be delivered on the resist.

- The system is considered flexible for the production of an infinite number of patterns.

- This technique is slower than optical lithography comparatively.

- For the production of highly resolute customized patterns, there is a need for an expensive amount of machines and tools. Therefore, to conduct this system is a little costlier.

- It can resonate with less than 10nm of resolution power. The resolution done is highly reliable and accurate.

- No requirement of using the photomask for conducting the resolution.

- The electron source used by the system is Hot W/ZrO2. This helps in emitting the electrons effectively.

- An electronic beam is induced with multiple layers of sensitivity for the process of diffusion or for the production of secondary electronic platforms.

- To avoid further charging effects, electrons are grounded safely. The process of grounding is done by adding a thin layer of aluminium or gold between the resistors.

- The electrostatic and magnetic lenses are used for the production of the EBL System.

- There are the chances of the occurrence of certain kinds of defects regarding the data related or physical defects.

- Use of interference lithography with the electron beams is advantageous as it gives out the shorter wavelength for the same energy.

- The introduction of Interference Lithography using the electron beams is another alternative path for patterning arrays with nanometer-scale periods. The advantage of using electrons over photons in interferometry is the shorter wavelength for the same energy

Elionix company’s partnership with STS is delivering nanotechnology products throughout North America and Europe. The Elionix electron beam lithography (EBL) system is known for fulfilling the demands for the finest lines.

Moreover, the company is known for the establishment of the world’s first 150Kv EBL system. This is used for research purposes.

Multiple types of lithographic systems have been introduced covering the ionic beam and the electron beam technology but Electron Beam Lithography System has been considered the best. As it is known for the most practical way of concentrating the most part of energy into the smallest area. To enhance the development of multiple electron beam approaches towards lithography, a huge number of companies are showing their interest in its instalment and management. These companies are SEMTECH, Multibeam Corporation, Mapper, IMS Nanofabrication